安徽省象形字数控机床有限公司是数控折弯机、数控剪板机等产品专业生产加工的公司,拥有完整、科学的质量管理体系。安徽省象形字数控机床有限公司的诚信、实力和产品质量获得业界的认可。坐落在中国经济发展的前沿—马鞍山 比邻 六朝古都 南京,占地面积6000平方米,现有员工200人,其中各级专精尖人才20多名。公司专业设计、生产、销售电液伺服数控折弯机、数控液压闸式、摆式剪板机及普通型液压折弯机、液压剪板机等板金加工设备,目前象形字已成为数控折弯机、剪板机生产基地之一。

销售热线:18155519839 技术服务:18055595108 (机床说明中英文双语版本)

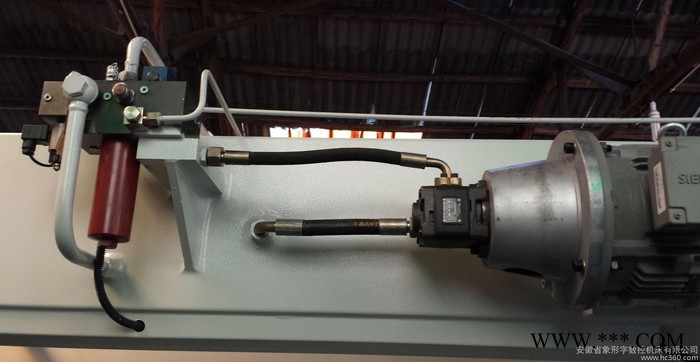

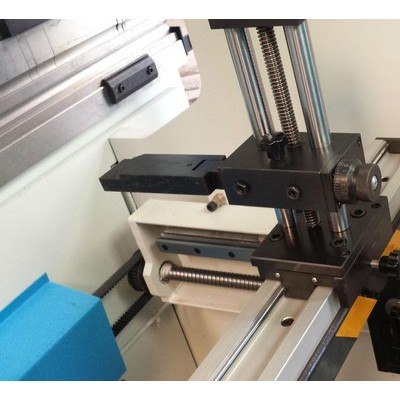

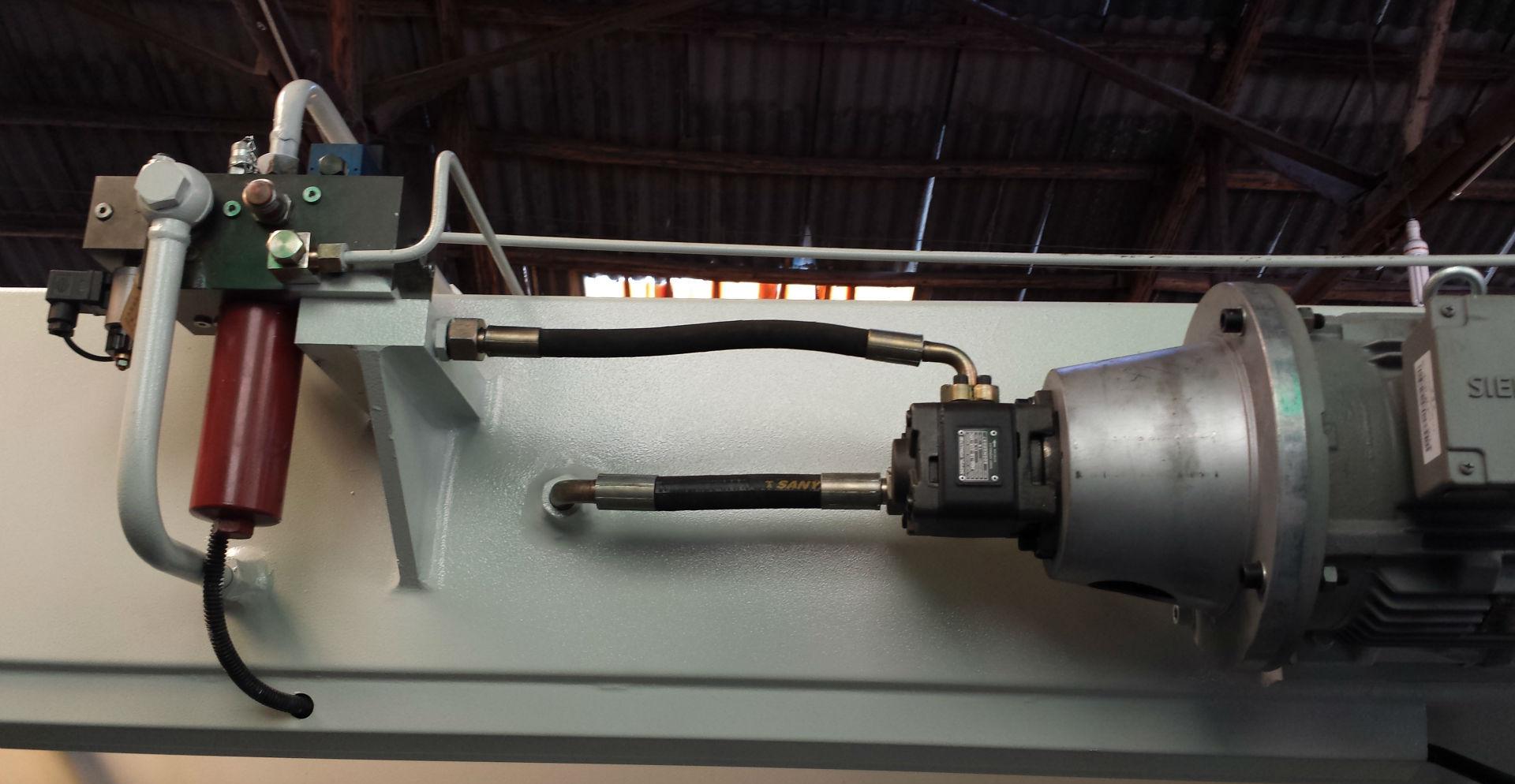

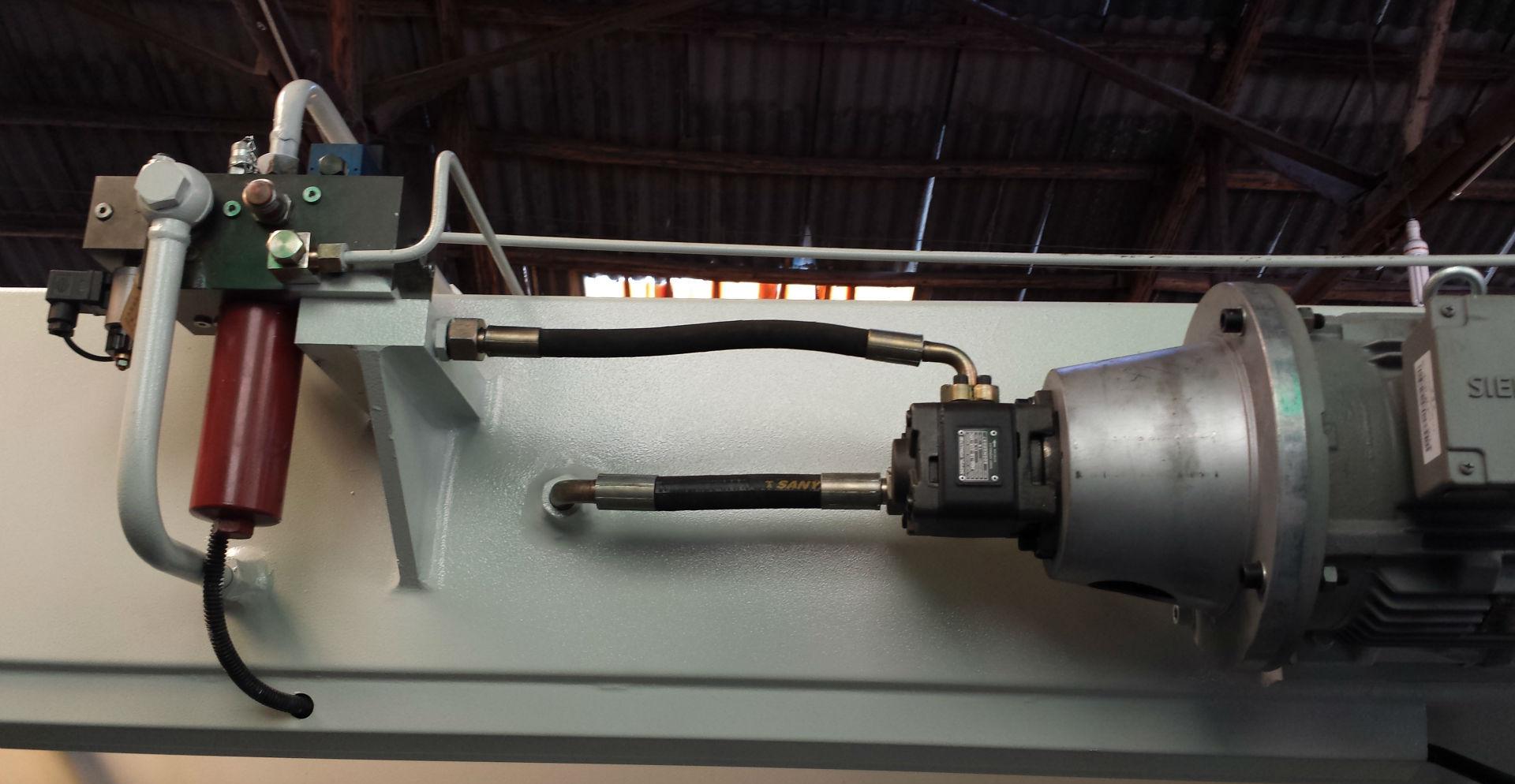

机 器 主 要 性 能:高效,节能,噪音低; 机 器 主 要 配 置:荷兰DELEM DA56S数控系统; 德国力士乐高性能电液伺服混合驱动泵控系统; 两侧配RSF光栅尺检测同步位置; 后档料配高性能伺服电机及滚珠丝杆; 采用CNC系统控制的WILA机械式下工作台挠度补偿装置; 配左右侧防护门及后防护门; 配简易直线导轨前托料架; Machine main performance:efficient, energy saving, low noise;

Machine main configuration:Holland DA56S DELEM CNC system;

The German lux Lego performance of the electro-hydraulic servo driven pump control system;

Synchronous position of RSF grating ruler detection for both sides;

High performance servo motor and ball screw with high performance of rear gear;

The deflection compensation device of the WILA machine with the CNC system;

Left right side guard door and rear guard door;

Simple linear guide rail front supporting rack;

折弯机机维护保养的方法 1、严格按照操作规程进行操作。 2、每次开机前按润滑图表要求定时、定点、定量加润滑油,油应清洁无沉淀。 3、机床必须经常保持清洁,未油漆的部分应涂抹防锈油脂。 4、电动机轴承内的润滑漾油要定期更换加注,并经常检查电器部分工作是否正常安全可靠。 5、定期检查链条、手柄、旋钮、按键是否损坏,磨损严重的应及时更换,并报备件补充。 6、定期检查修理开关、保险、手柄、保证其工作可靠。 7、每天下班前10分钟,对机床加油润滑及擦洗清洁机床。 8、严禁非指定人员操作该设备,平常必须做到人离机停。

A method for maintenance of bending machine

1, strictly follow the operation procedures for operation.

2, every time before the start of the lubrication chart to require the timing, fixed point, quantitative lubricating oil, oil should be clean without precipitation.

3, machine tools must often keep clean, the part of the paint should be coated with rust preventive grease.

4, motor bearing lubrication overflow oil should be changed regularly filling, and always check whether the normal work of safe and reliable electrical parts.

5, regularly check the chain, handle, knob, key press whether damage, wear serious should be replaced, and to spare parts for spare.

6, check the repair switch, insurance, handle, guarantee its work reliably.

10, 7 minutes before work every day, lubrication and cleaning machine tool for machine tools.

8, non designated personnel to operate the device, usually must be done to stop the machine.

|